If this is the first you’re hearing of RMR cuts on the Ghostgunner the first thing you might want to check out the video of James from TFB covering our development version of the jig and code during an interview with a member of the Ghostgunner crew at their both last SHOT Show. Scrub to the 1 minute mark to see our RMR cut being introduced.

We haven’t worked much on the design until recently due to our move down from Washington to Nevada, this new website development, GG3 testing and code development, and life in general, but we’re finally coming back around to this project.

The most recent work has been in trying to bring the cost of the production of the jig down to more reasonable levels. Our prototype jig was somewhat complex and wouldn’t be a feasible option for true production especially since it looks like we aren’t going to be able to have a big boy CNC machine in-house for at least some time longer. Once we can get the capital we need to get that piece of equipment we’ll be able to get the costs down even more.

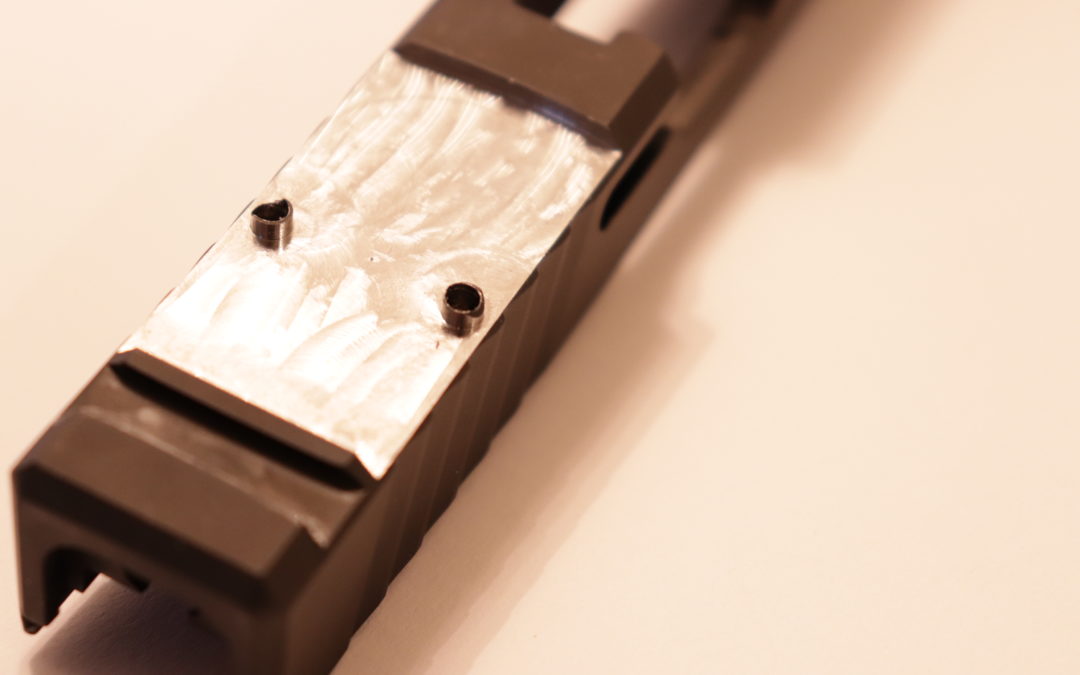

another focus is on making sure that we can get the most useability out of the jig by trying to design it such that it can accomodate multiple different slide variants as well as allowing not only the top of the slide to be milled, but also the sides as well. We’d like this to be less of a specifically Glock RMR cutting jig and more of an all-purpose workholding solution for slides allowing the potential for profiling, lightening cuts and engraving.

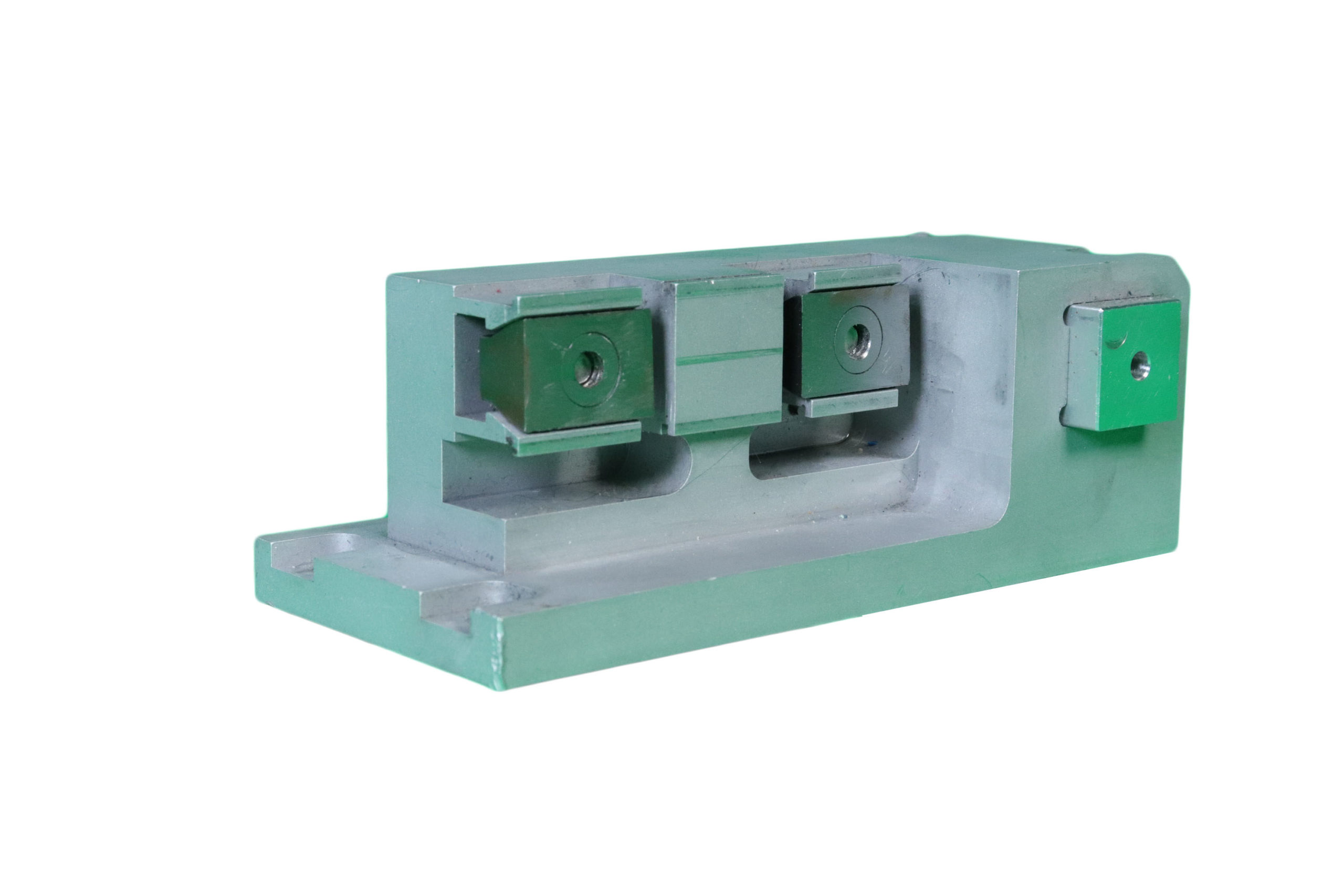

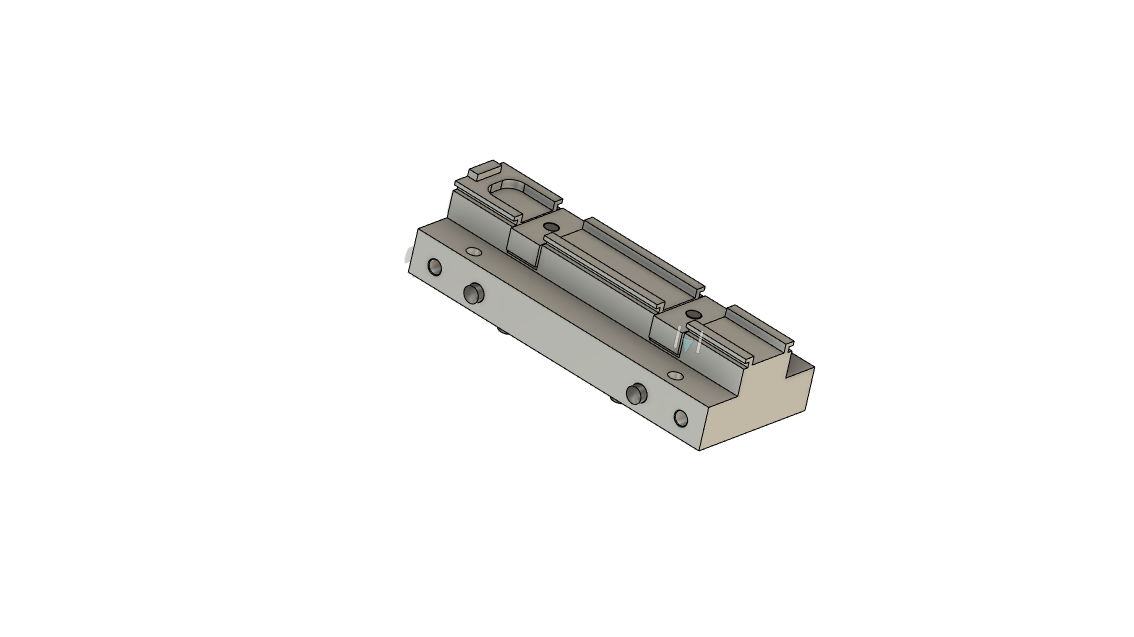

Here’s a look at the old jig and the current model for the new design:

Any work on a jig that would work with a sig p 226 frame

Actually we’re hoping to have this jig be something that can work for a variety of slides including potentially having it be modular to support even more frame types. The part that may take longer is that in order for it to be easy to use code would have to be developed that either took into account that specific slide or be generic and the user would have to know whether it would be compatible with their given slide.

We don’t have a P226 slide on hand to test with, though so at this time we wouldn’t be able to say if it is compatible currently or not.

I have built several Sig P320 pistols are you working on codes to mill any of the with the ghost gunner3. Would like to do one of them on the machine. I have done 3 with the JSD jig now, planning on in future to do a couple more .

Both of the owners here at GGD actually love the Sig P320 pistol and concept. That being said we have a ton of other projects we are working on at the moment and something like this is unlikely to be something we tackle until further down the road.

We would definitely love to partner with JSD on a project like that though since we know the owner and he’s a great guy to work with. If nothing else feel good knowing that buying from JSD means you’re buying from a solid company with solid folks.

Any updates?

Have you done any using the GG3 by any chance?

Not yet although we plan on circling back to this project as soon as we get the Universal AR-15 Fixture orders out

How’s this coming along?

It’s actually coming along well. If it weren’t for the move and the myriad of blockades that have popped up with the universal AR-15 project we’d already have this out.

will the GG3 be drilling and tapping the holes for the RMR

Yes…no…maybe? haha we certainly plan to have it drill the holes, but we aren’t 100% on tapping. We will try seeing how viable single point threading would be, but based on costs or other limitations we may go with hand tapping although we would like to avoid this because, with such small taps, breaking off a hand tap is much more likely than with bigger tapped holes.

Guys you’re kind of reinventing the wheel here aren’t you? Why not just use a wedge or clamp block that accepts MGW sight pusher shoes? They’re easily available, and the block would be cheap enough to mass produce that way. Anything that holds a slide well enough to push XD sights out ought to be able to handle RMR cuts and engraving…

Agreed

Agree on MGW sight pusher

shoes. Great idea !

Will the RMR cut be only for GG3 or will the jig work for a GG2?

We’re currently developing for the GG3, but will assess the feasibility of it being done on the GG2 after we finalize the GG3 design and cuts.

any new updates on this project?

Actually, yes! We have a new version we are testing that integrates with the new base plate system used in the AR-15 universal project. First we need to finish up that project and then we’ll move on to this.