*Note that YOU WILL RETAIN YOUR PLACE IN LINE from your original order if you choose to purchase this upgrade

Expected to Begin Shipping:

GG3 Version: Late April

GG2 Version: Early June

Expected New Order Ship dates:

GG3 Version: Mid May

GG2 Version: Mid June

To our Supporters: Those people that have been our Patreon supporters and those that are subscribed to our paid memberships will receive their units first. All others will be on a first-come first-served basis once they start shipping. Also a small number of our biggest supporters may also be asked if they are interested in testing a beta version of these fixtures and the associated code free of charge rather than having to wait for the official release. Those that test will keep the beta fixtures and if they ordered them here as well they'll still receive the official release version as well.

*The base milling codes for using with this fixture are included with your purchase and will be included with your order when it ships

*This fixture does not include the collets or end mills/drill bits needed to mill a lower as it is expected that you already have those. There is an additional add-on for those that need it.

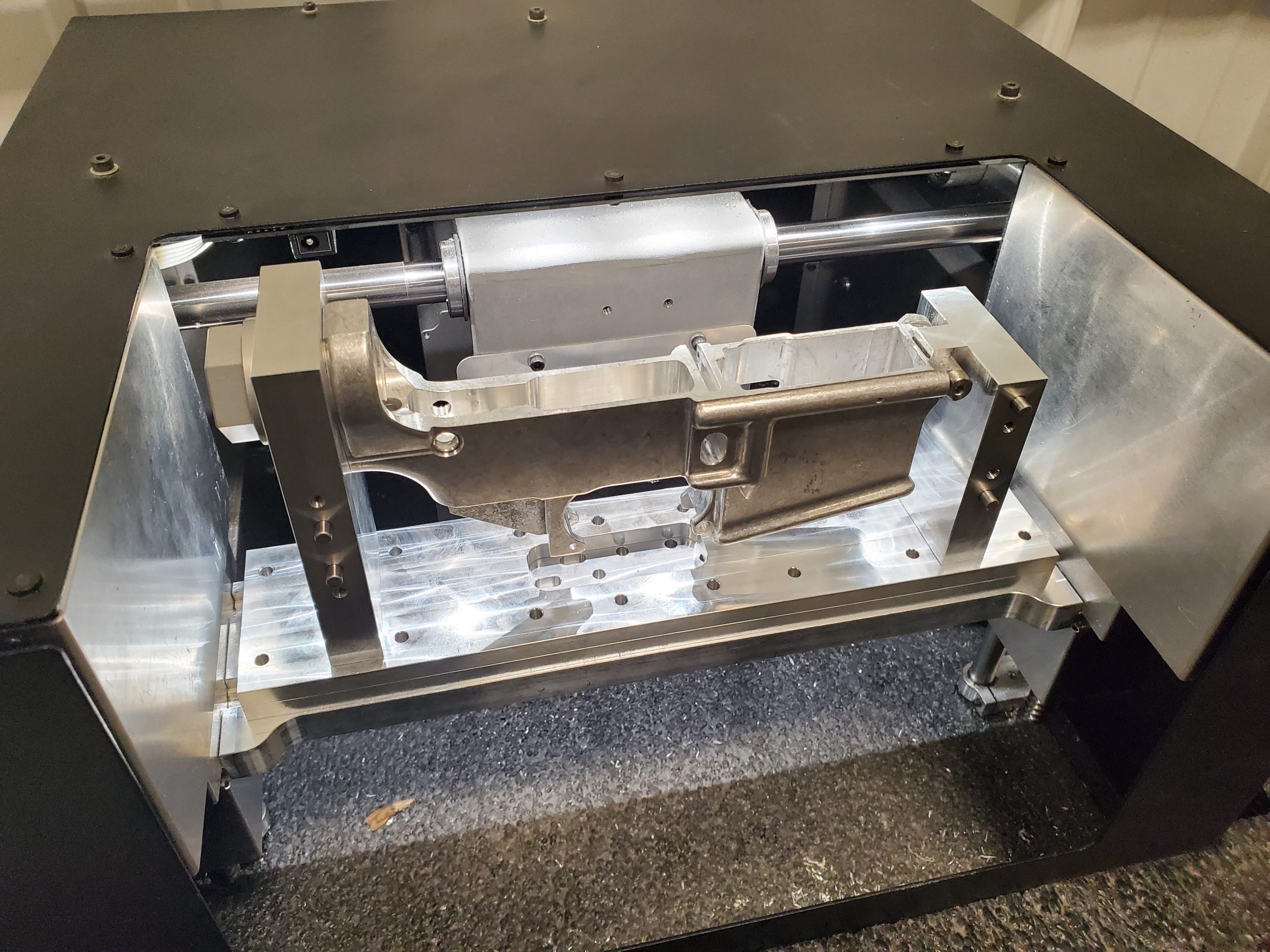

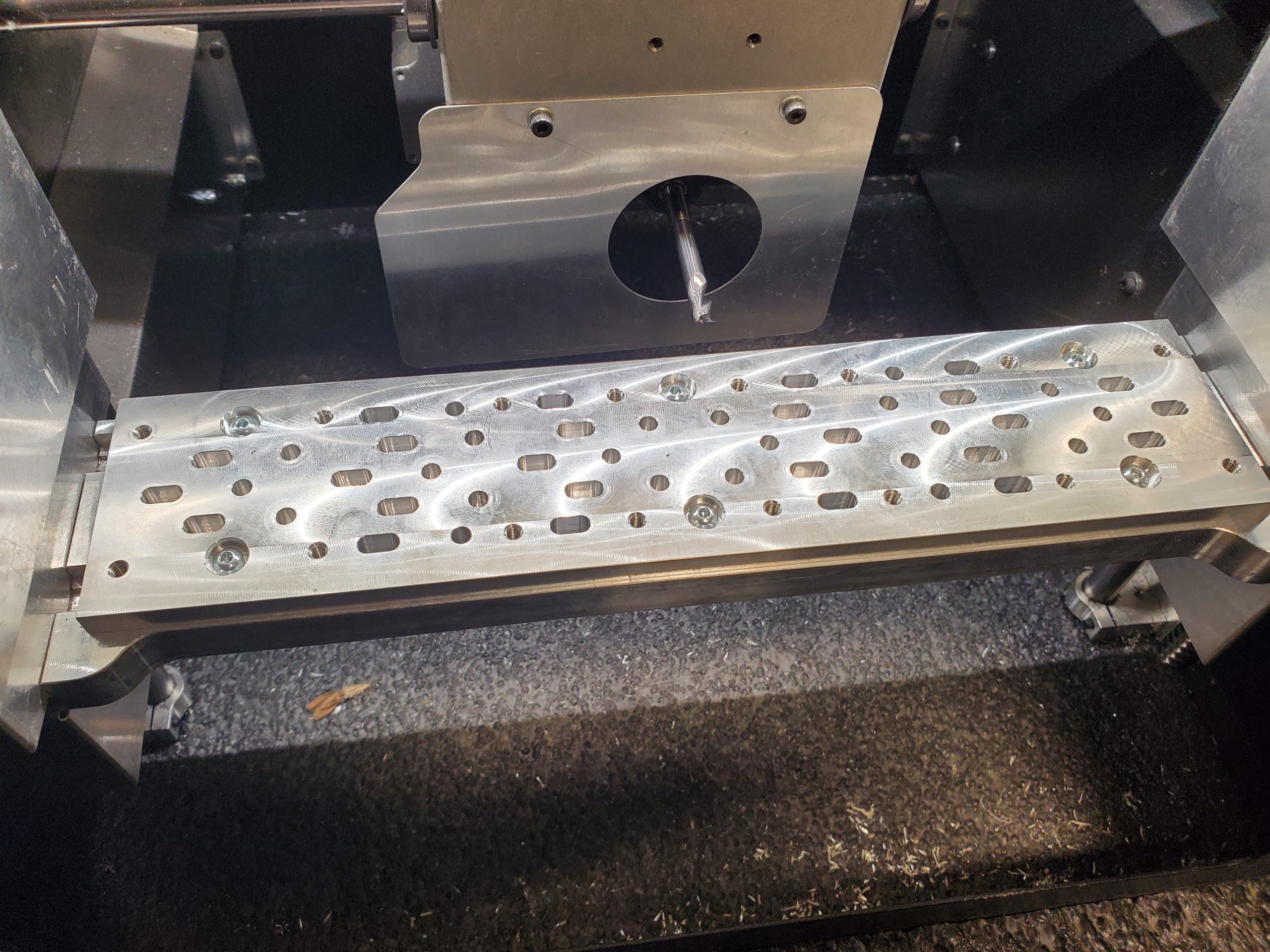

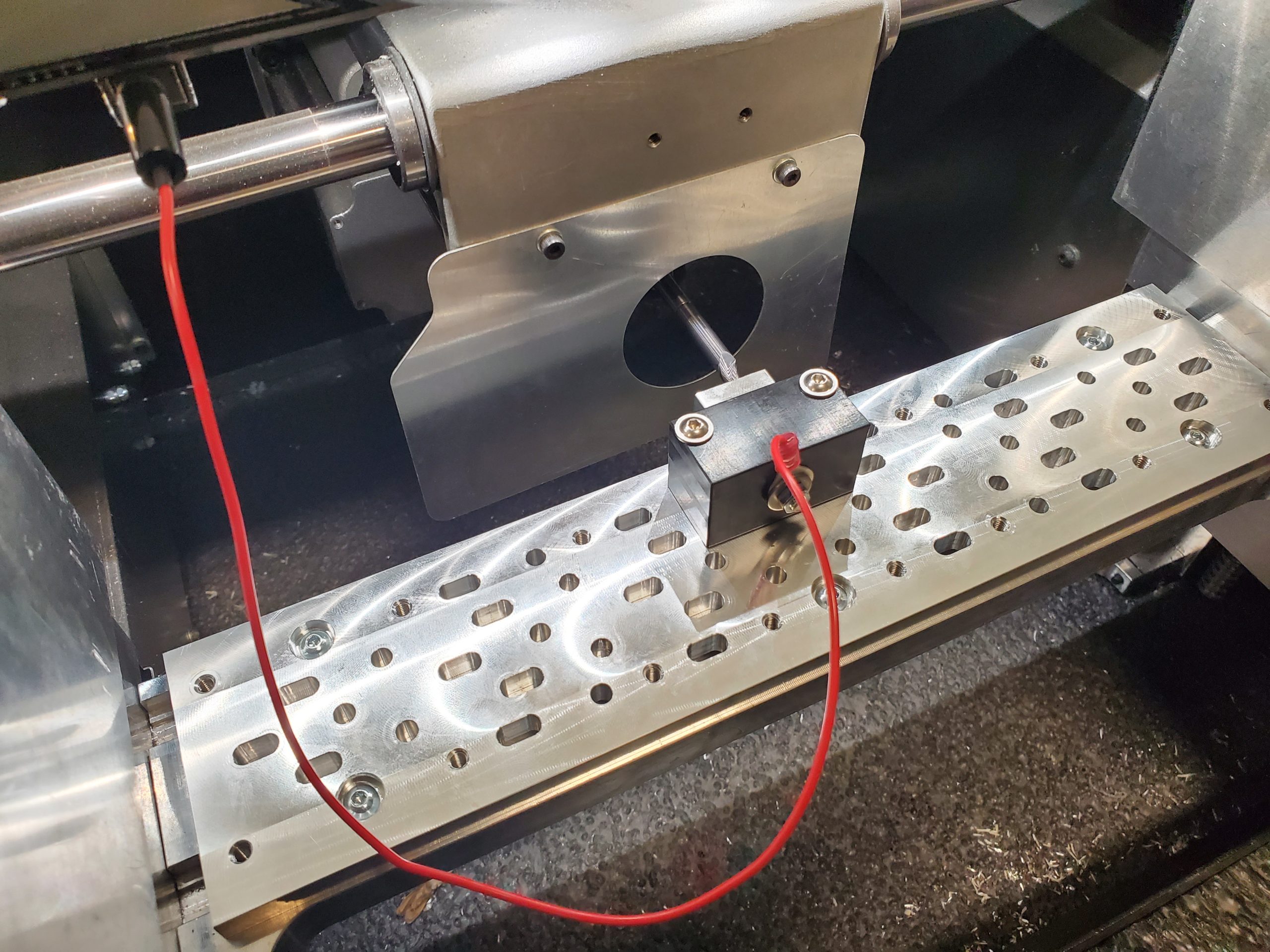

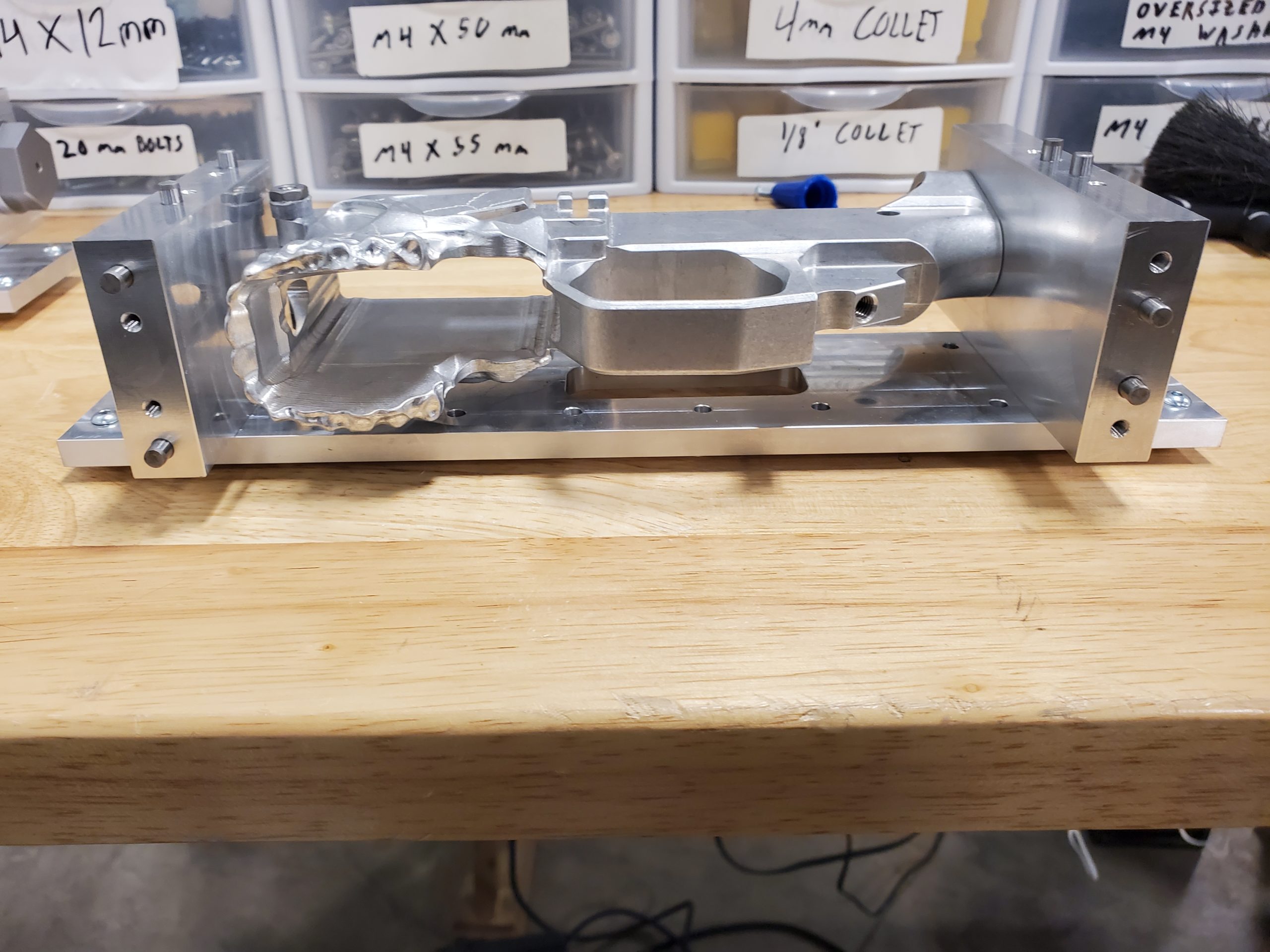

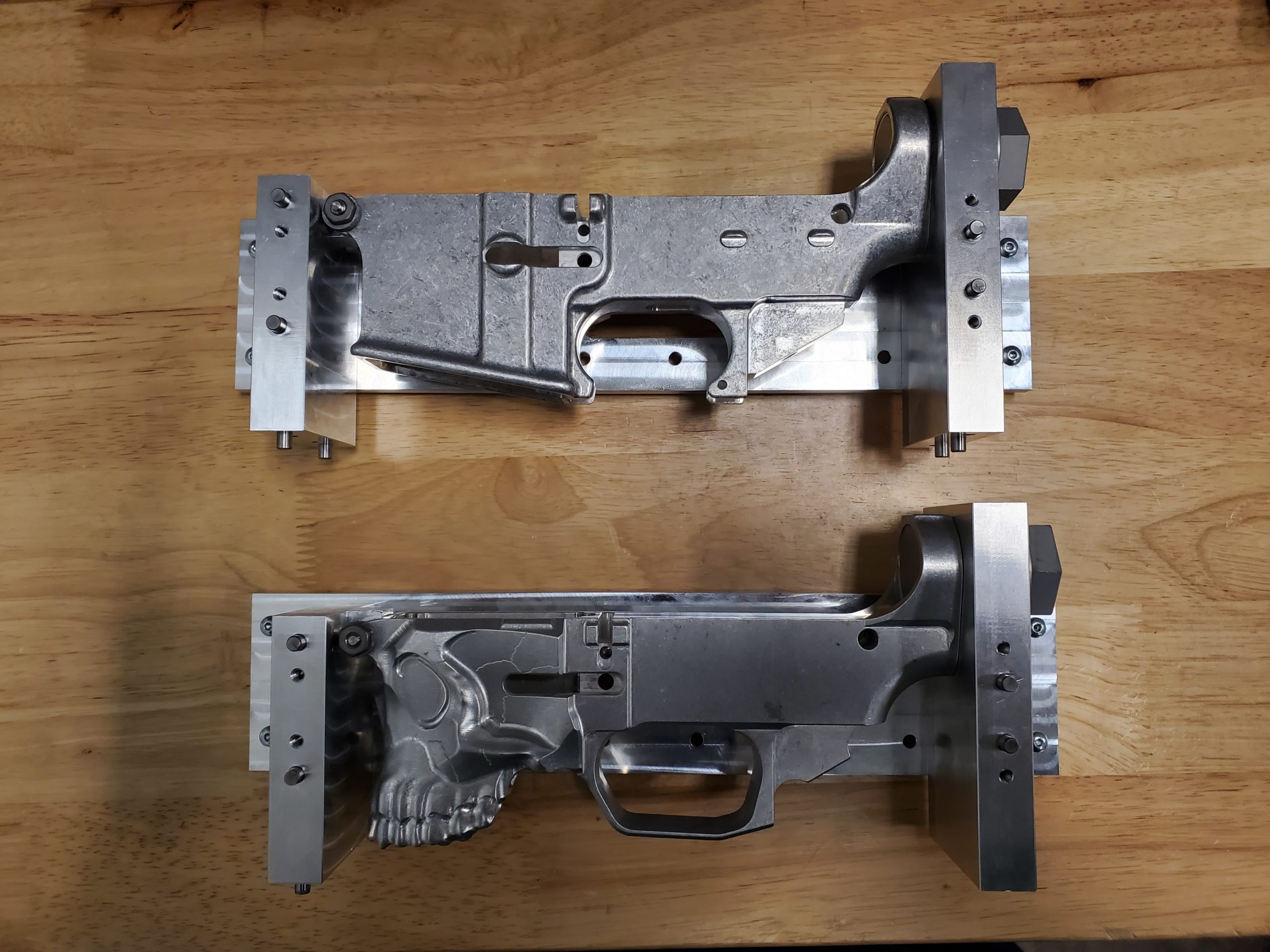

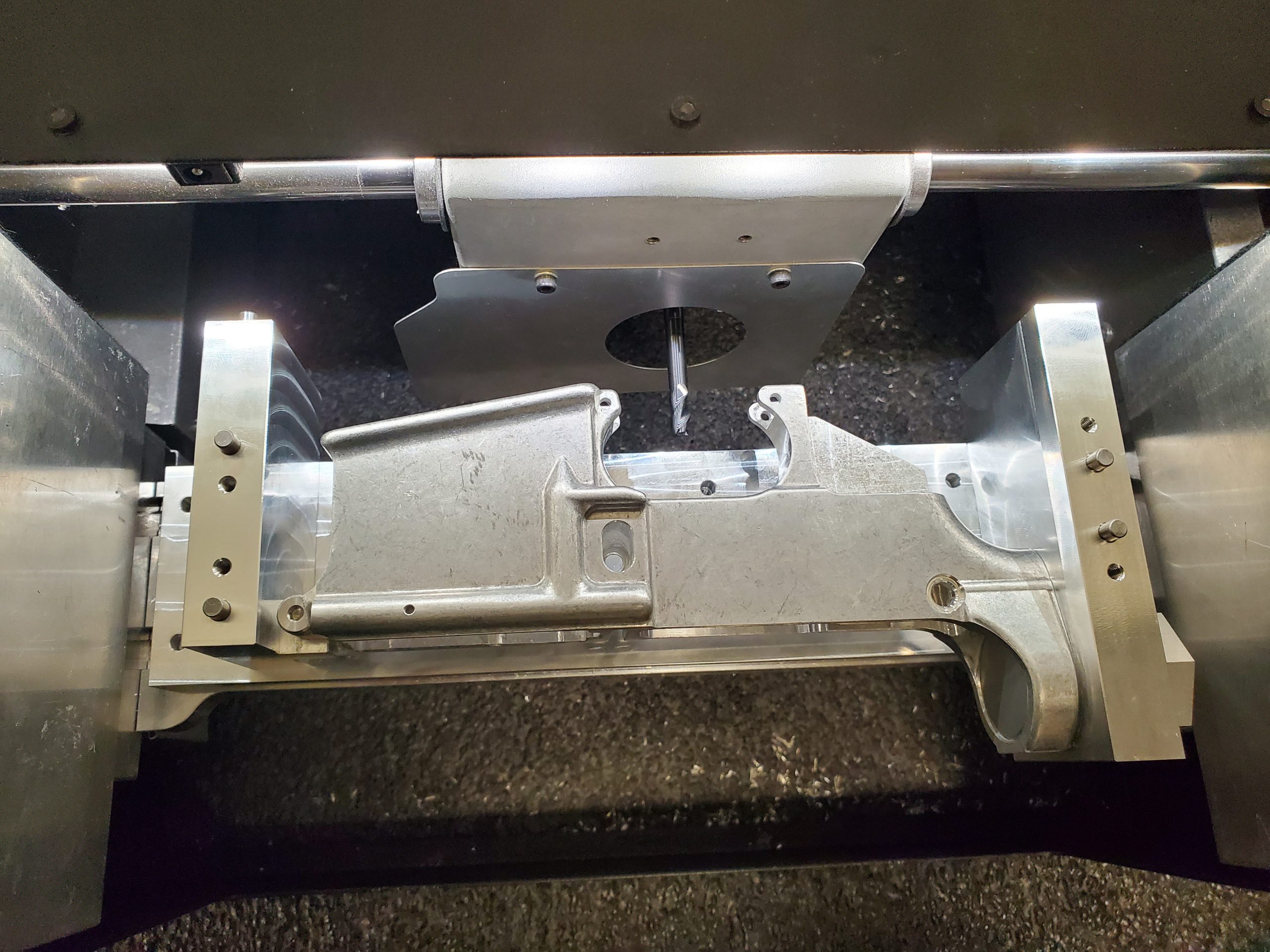

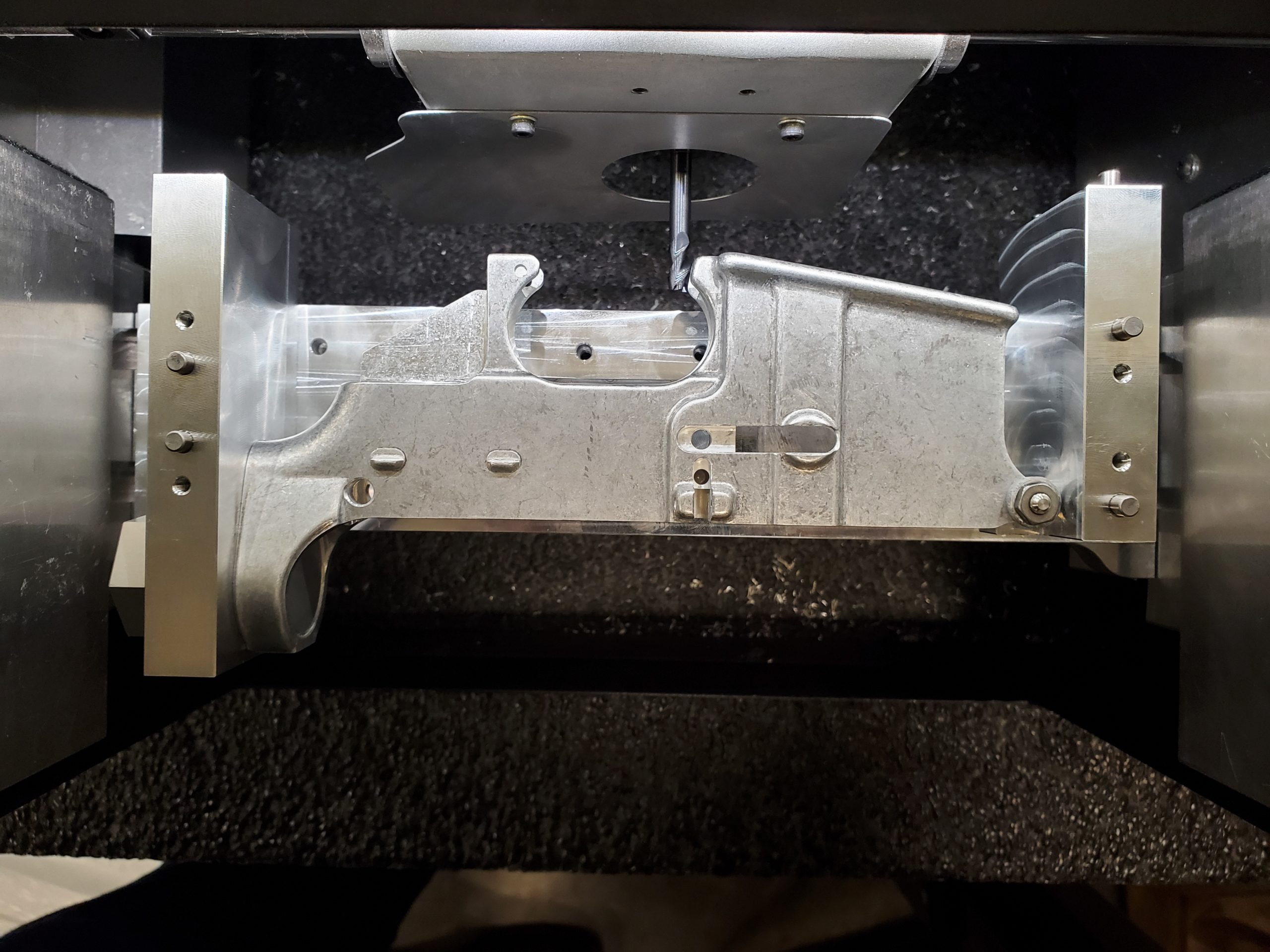

Made in-house in the USA by GGD, made out of aluminum, and made to last

*Slaps the top of the Jig set* This baby right here will do it all

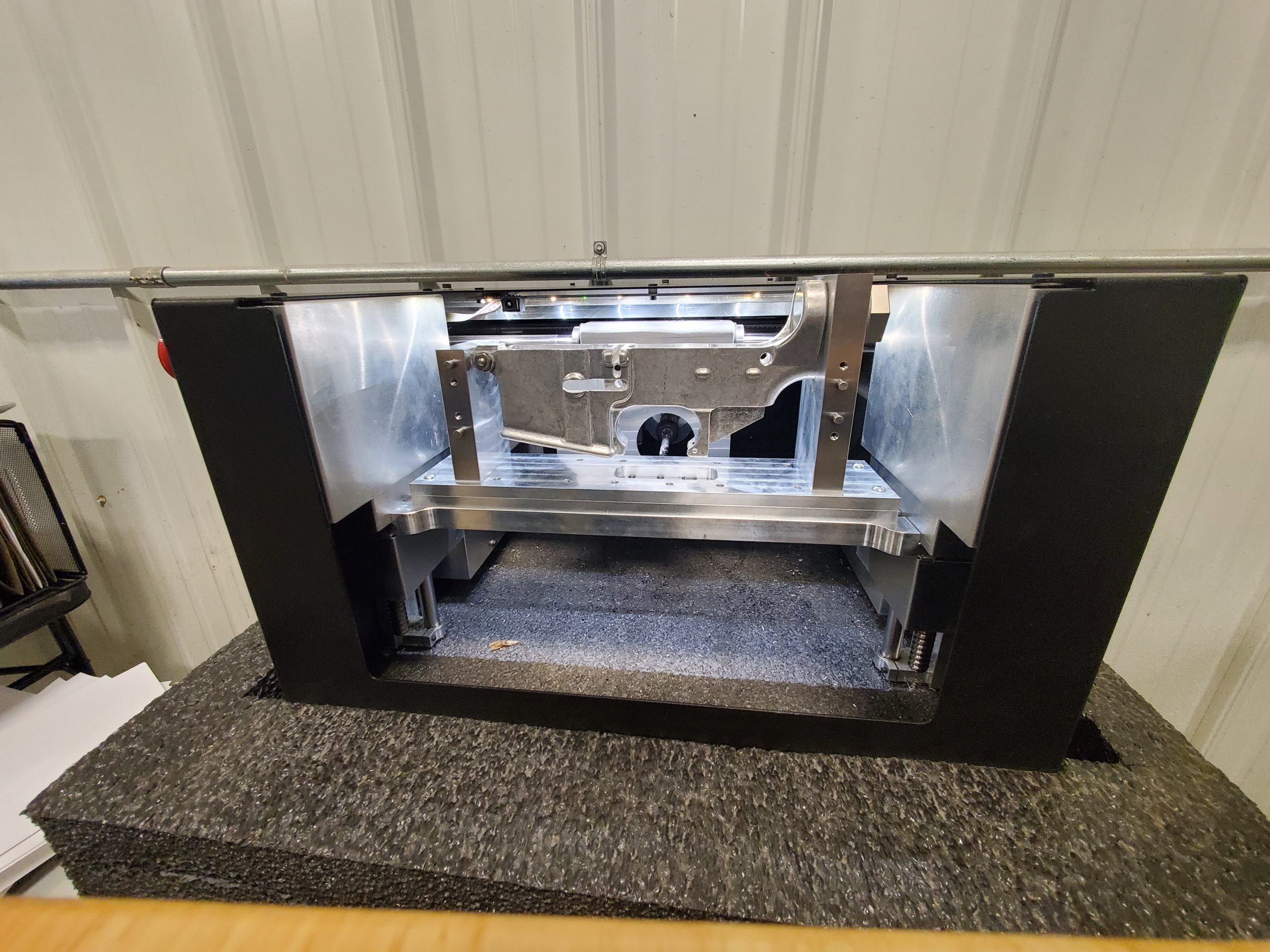

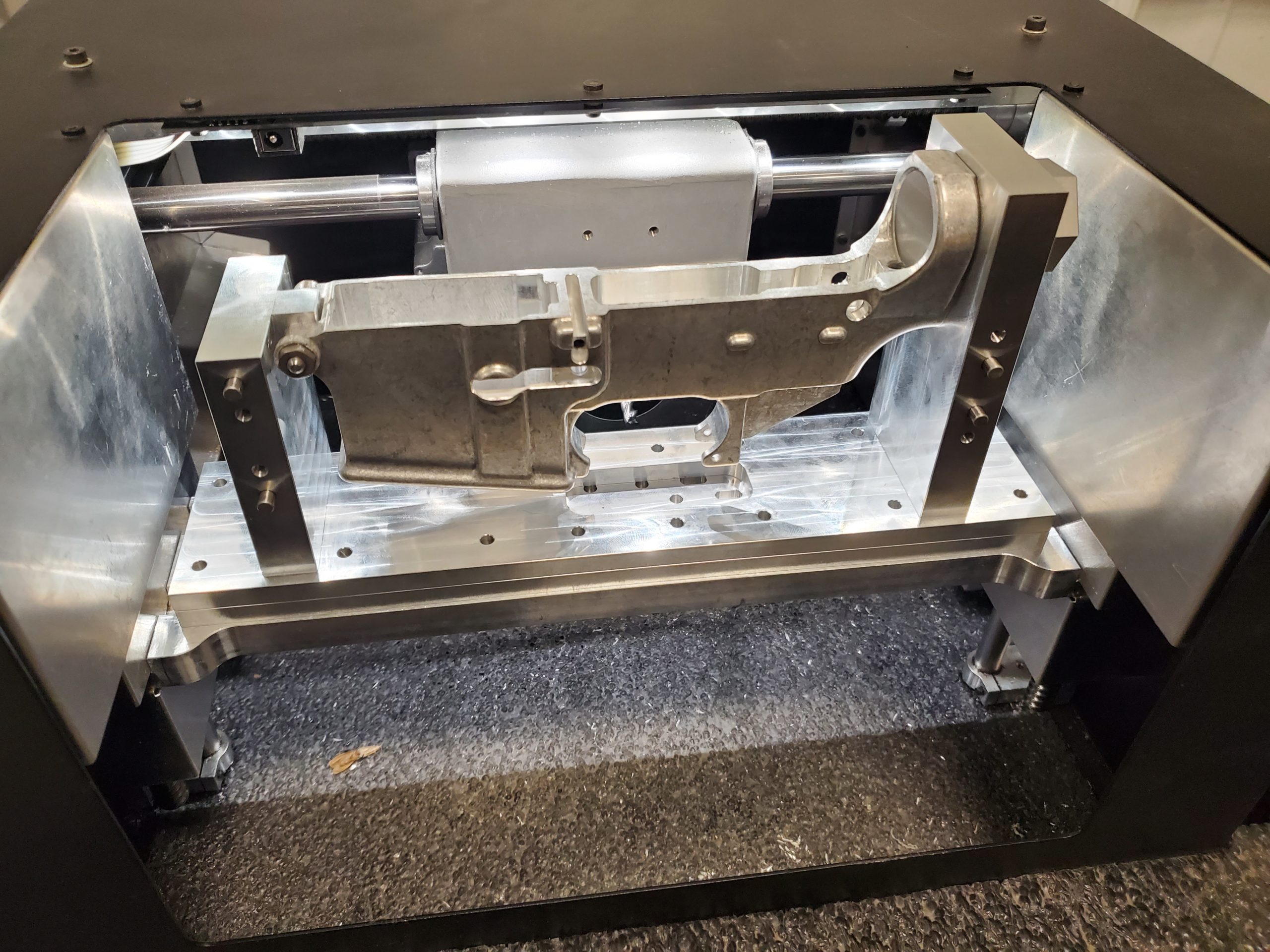

Main Description: This is for our big ballers out there or those that value their time and love a much simplified way of using their Ghost Gunner. Ideal for FFL's or those of us that love this hobby so much it's probably less like a hobby and more like an addiction! Comes with a base plate/fixture that drastically simplifies the process of running an 80% on the Ghost Gunner. It also allows for much more quickly swapping from one lower/job to another without the need to have to reprobe the lower. Instead the machines probes the base plate ONCE and then as long as you don't remove the base plate, crash the machine, or power down the Ghost Gunner you don't need to reprobe again meaning if you purchase a second set of the fixtures to have a lower on standby ready to go you could finish one lower and be able to pull it out and start a new one in under a minute!

Main features of our Universal Fixture:

Milling-

-Will work with virtually ANY 80% built off of an AR-15 pattern. This includes AR9's, AR45's etc. As well as lowers with large flared magwells or large integral trigger guards.

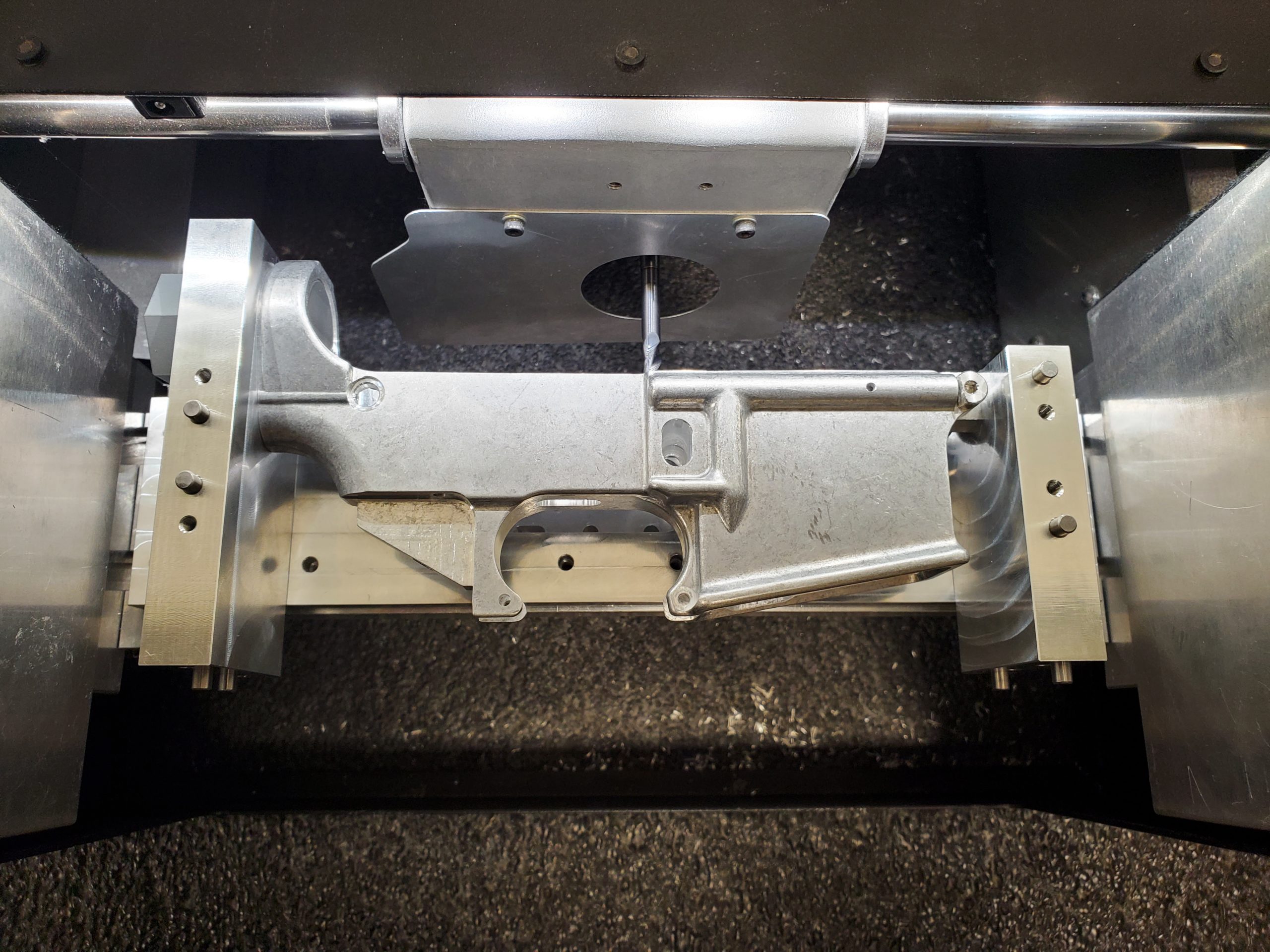

- No more offcenter pockets. Accurate placement of FCG pocket, safety selector hole as well as the trigger and hammer pin holes, due to referencing off of a consistent datum (front takedown pin) rather than the pistol grip pocket or inside of the magwell, which varies between manufacturers.

- No more misaligned safety selectors that sit at weird angles

- No more incorrect/inconsistent placement of hammer and trigger pins. With this fixture you can finally count on the Ghost Gunner to do all 80% machining required without worrying about incorrect placement of drilled and milled holes.

- No need for multiple different .dd files. Due to the previously mentioned accurate placement of features there is no need to have different codes for different manufacturers.

- Can handle whatever the Ghost Gunner can throw at it without fear of melting jigs or poor cut quality.

- Seamlessly mill the rear takedown pocket at the same time as the main fire control group pocket. Since there is no need for a bolt that goes through the rear takedown pin hole means the entire pocket, INCLUDING the rear takedown pocket, can be machined in one go without compromising the rigidity of the fixturing or issues with misalignment between rear takedown pocket and main pocket.

- Mill or skeletonize practically any area of the lower thanks to the completely open design of our fixture as well as its rock solid rigidity

- Super secret utility that is currently in development that will utilize this fixture. Let's call it...Project Zero

Skeletonizing:

- Due to the vastly increased rigidity of this workholding solution, skeletonizing jobs can be done in a fraction of the time due to the elimination of vibration present in plastic fixturing.

- Completely open design leaves the entire receiver open to be skeletonized

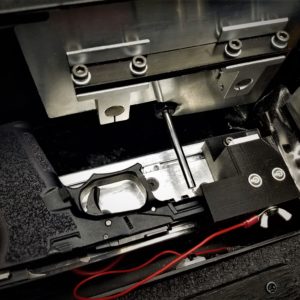

Engraving: (Note that if you don't purchase the optional engraving sub-plate that you will need to use special tape in order engrave due to the need to probe the surface of the lower)

- Will index much more accurately than current engraving jigs/fixtures

- No need to reprobe between engravings on the the same side (useful for FFL's doing the same logo or multiple serials one after the other)

- Completely open design will allow the entirety of the lower to be engraved without the fixture interfering while still being the most rigid and accurate fixturing for the AR-15, to date.

- More accurate placement of engraving due to referencing off of a consistent datum (front takedown pin) rather than the pistol grip pocket which varies between manufacturers.

- No more faded engravings

- Substantially reduced engraving times

- When paired with the optional Engraving Sub-Plate there is no need to use an end mill when engraving. Simply leave your engraving bit in if you are doing more than one engraving. Thanks to the base plate once it has been probed the very first time there is no need for anything other than an engraving bit when running engraving jobs.

- Virtually ELIMINATE the need for probing! No need to probe more than once after starting your machine until you shut it down again provided you don't move the base plate or the machine doesn't otherwise lose track of it's position. This means you can move right from milling the FCG/rear takedown pocket to drilling or milling the pin holes (that's right, milling, not drilling the pin holes) to engraving your lower immediately after milling the pin holes

- When combined with an added purchase of an additional set of the main fixtures will allow the user to have a new lower on standby ready to place in the machine and mill the moment the previous lower is completed. Disassemble the one you just removed and install it on another while the other lower is milling and you're ready for the next one when it completes. Rinse, lather, repeat.

- Potential to support other platforms as they are made high-volume capable to make it trivial to switch between different platforms such as P80, AR-10, 1911, etc with no need to reprobe or do any complicated setup.

Additional High Volume Fixture Sets: Buy an additional set of our High Volume Fixtures so you can have a lower on standby already assembled with the fixture to swap in when your currently being milled receiver finishes. doing it this way can allow you to have a new receiver being milled in under a minute from when the last one finished.

Additional High Volume Base Plates: The only real reason you would want an extra base plate is if you have multiple Ghost Gunners and want to maximize your throughput by having a base fixture on each of your machines to make use of our Universal Fixtures on multiple machines at once.

Engraving Sub-Plate: The optional sub-plate is used to make it unnecessary to use special tape to engrave using the all-metal universal AR-15 fixture. Due to the fixtures all-metal construction it is inherently not electrically isolated between it, the lower receiver, and the T-slot plate, which, due to how the Ghost Gunner detects probing, is required when probing the surface of the lower receiver itself. This sub-plate is made of an electrically non-conductive material which, while not suited for milling, works perfectly for engraving. This sub-plate also allows for rapid turnaround for switching from engraving one lower to engraving the next due to not needing to reprobe anything other than the surface of the lower itself.

Additional information

| Weight | .1 lbs |

|---|---|

| Dimensions | 1 × 1 × 1 in |

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.